Food Safe Epoxy – Helpful Guide to Food Grade Epoxy Resin

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

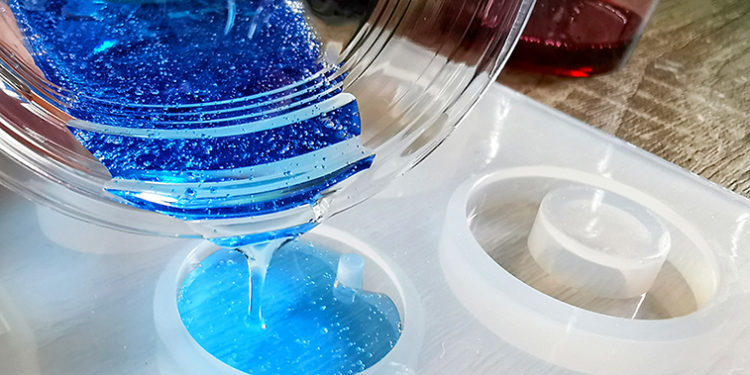

Working with epoxy resin has many advantages: The material is very versatile and can be used in many areas. However, the resin also has some disadvantages. These include first and foremost the health aspects. In this guide you will find information about how food-safe epoxy resin really is, and what to consider in this context.

Table of Contents

- 1 Is Epoxy Resin Toxic?

- 2 Best food safe Epoxy Resins Overview

- 3 Food-safe Epoxy Resin with Test Seal

- 4 Certification in the EU only for Selected Products

- 5 What is Food Grade Epoxy Resin?

- 6 Hazardous Ingredients in Epoxy Resins

- 7 How can you Know how Harmless the Epoxy Resin used is?

- 8 Notes on Work Safety

- 9 Early Treatment of Skin Disorders

Is Epoxy Resin Toxic?

Two basic statements can be made about the toxicity of epoxy resins:

- Liquid epoxy resin is always toxic

- When cured, the resin is non-toxic

A fundamental answer to the question of whether epoxy resin is toxic or non-toxic is not possible. This depends first and foremost on the chemical composition of the respective products, which can vary depending on the intended use.

One epoxy resin can therefore be more harmful to your health than another. Nevertheless, you should always protect yourself as best as possible when working with any resin. Never touch the resin or hardener without protective gloves. A breathing mask can protect you from the harmful vapors. It is also a good idea to use safety goggles so that no resin splashes accidentally into the eyes.

You should avoid inhaling the vapors produced in the liquid state as much as possible. Direct skin contact with the resin is essentially more harmful to health than the vapors. However, the effects of the inhalation of epoxy resin vapors is greatly underestimated. Immediate symptoms such as skin rashes may occur as your skin reacts to the liquid resin.

In the meantime, some casting resins consist at least partially of natural ingredients. In the liquid state, however, even these are toxic.

Best food safe Epoxy Resins Overview

STONE COAT Countertops Art Coat

Stone Coat is always a leading brand when it comes to epoxy resin, and this product has been specially formulated for use on countertops. The food-safe resin has zero VOC, is heat resistant, UV protected and dries crystal clear.

While this resin has been specifically designed for tabletop and countertop use, it can be applied to various surfaces and materials that require a food-safe resin coating. The resin also works particularly well with pigments, tints, and coloring – so it is a great product choice for anyone wanting to get creative.

- Specifically designed for art projects, developed with professional artists

- Heat resistant, scratch resistant, food safe, maximum UV resistant, water resistant

- Compatible with alcohol inks, acrylics, silicone oils, metallics, dyes, pigments

The durability of this epoxy makes it an excellent choice for DIY projects and home use. It also works well in art projects. The resin has a 45 minute working time before drying, and should take around 24 hours to cure completely.

Pros

- UV resistant, scratch-resistant, and very durable

- Has a certain level of heat resistance

- Works well with coloring

- Easy to mix and available in a large volume

- Food safe for various surfaces and applications

Cons

- Has a slightly faster work time

- Can be difficult to get all of the air bubbles out

MAX CLR Clear Epoxy Resin Kit

This epoxy resin by Max Clr is available in a range of different size options depending on your project. As it is a food-safe resin, it is well suited for use on countertops, tabletops, cutting boards, and any similar applications.

When applying this epoxy resin, you get a 70-minute working period before it dries. Then the resin will take at least 24 hours to completely cure. This 2 part resin is easy to work with and apply. While it is still wet, it has a low viscosity, making it easy to fill in any gaps and spaces. The only problem with this is that it can be a little tricky to apply the resin to any surfaces that are not level. This is because you can get quite a bit of run-off which can cause an uneven coating.

- Crystal Clear Coating For Wood And Other Porous Substrates

- FDA Compliant Coating For Direct Food Contact

- High Gloss Sealant- Prevents Absorption, Impact Resistant, Durable Coating, Sanitizable

This epoxy has an FDA approval for brief contact with foodstuffs, making it a great choice for covering surfaces where food is prepared. In fact, you could even use it for ceramic coatings – such as bowls and mugs. The only downside is that this superior food-safe protection comes at a slightly higher price than other epoxy resins.

Pros

- Easy to work with and mix

- Offers a superior food-safe surface

- Durable and easy to clean

- Can be used on a wide variety of surfaces

- Works great as a sealant

Cons

- A more expensive epoxy resin

- The epoxy can run quite easily when applying it

ZDSTICKY Clear Epoxy Resin

This is a very user-friendly resin produced by ZDsticky. The resin comes in easy to use plastic bottles and can be mixed to the perfect consistency without too much difficulty. This epoxy resin was actually designed for jewelry making, which means that it has a much thicker consistency than other resins.

While the thickness makes it convenient in some ways, it also makes it more difficult to get perfectly even smoothness. You also tend to get more air bubbles trapped in this resin. The resin should take 24 hours or longer to cure. Once dried, this resin is beautifully clear, glossy, and durable.

- Zdssticky resin is food-grade safe and environmentally friendly

- It can be used to contact food after curing

- Special formulation for a lower bubble generation rate

The ZDsticky resin is completely food-safe and can be used on any surfaces that will come into contact with food. These include countertops, cutting boards, mugs, bowls, or anything else. Of course, this resin is also ideal for jewelry making.

Pros

- Easy to handle and mix

- A thicker consistency resin

- Cures crystal clear and glossy

- Very durable

- Completely food safe

Cons

- The resin can be difficult to get perfectly smooth

- Can be tricky to get air bubbles out

Food-safe Epoxy Resin with Test Seal

If synthetic resin is to come into contact with food or the skin over a longer period of time, it is important to clarify in advance how food-safe epoxy resin is.

This is the case for example with:

- Coatings of food tanks

- Molds used in the food industry (e.g. chocolate molds)

- Household articles, e.g. fruit bowls or cutting boards

- Furniture made of epoxy resin, especially epoxy resin tables

- Interior coatings of ponds

- Aquariums or terrariums

- Prostheses

- Orthoses

First the good news: In the EU, the food safety of the resin is marked with its own test seal. There are specially developed products with this seal for the above examples. However, in the case of short-term contact, any commercially available epoxy resin is food-safe and therefore harmless.

Tip: The epoxy resin is non-toxic or food safe only after complete curing. In a liquid state though, the synthetic resins and the resulting vapors are always toxic! You should therefore take care that your skin does not come into contact with the liquid resin.

Certification in the EU only for Selected Products

A few years ago, the various countries individually determined which standards and certificates were necessary for an epoxy resin to be considered food-safe. After a uniform EU directive was introduced, many manufacturers did not have their products tested again and therefore could not obtain a test seal.

On the one hand this is due to the fact that the approval is very expensive for the manufacturer. On the other hand, the obtaining of the seal is attained with a much effort. Therefore, there are only a few epoxy resins with this seal of approval on the market and they are correspondingly expensive.

Accordingly, in the USA the FDA is responsible for the evaluation and certification of epoxy resins.

What is Food Grade Epoxy Resin?

There is no clear definition of what makes a material a food safe material. However, some requirements must be met in any case. These include, for example, the food conformity requirements of the Food and Drug Administration (FDA) in the USA, the Federal Office for Risk Assessment and the requirements in accordance with EU Regulation No. 10.2011.

In principle, a material can be described as food safe if it can come into direct contact with food without posing a health hazard. That means:

- No taste or smell from the material is transferred to the food

- There is no health hazard if the food is consumed after contact with the material

- The material does not release any, or releases very few, free components into the food

- The composition of the food does not change through contact with the material

In case of doubt, contact the manufacturer in advance to find out whether the product is food safe. In order to obtain the best possible quality of the epoxy resin, it is also important to adhere exactly to the recommended mixing ratio during processing.

Hazardous Ingredients in Epoxy Resins

Carbolic acid / phenol

Carbolic acid is nowadays used in agriculture as a weed killer. It is rarely used as a disinfectant at low dosages. In high doses it is considered a nerve or cell poison and can cause chemical burns on contact with the skin.

Epichlorohydrin / prepolymers and diglycidyl ether

These substances can cause allergic reactions upon contact with the skin. The occurrence of contact eczema that cannot be treated is also possible. The effect of both substances in combination is not yet known. Exposure to high concentrations of epichlorohydrin or diglycidyl ether over a long period of time could possibly cause cancer. In addition, escaping vapors can lead to paralysis of the respiratory tract, irritation of the mucous membranes or delirium. In case of very frequent and long contact, nerve damage or kidney damage is also possible.

Tip: The products available on the market show strong differences in their toxicity. Products for do-it-yourselfers and craftsmen are generally less hazardous than so-called industrial goods. These are designed to be processed in factories within isolated rooms with an extraction system, which is why they often contain more toxic substances. You should therefore not save at the wrong end in favor of your health and the quality of the product. The industrial goods that are more harmful to health are in fact considerably cheaper than products for private use.

How can you Know how Harmless the Epoxy Resin used is?

If you have any questions regarding the food safety and toxicity of your resin, it is best to contact the manufacturer directly. As a rule, the safety data sheets of the products are made available on the manufacturer’s website.

Here you can inform yourself about the classification of the ingredients of a certain casting resin. The hazardous substances label is also informative. If in doubt, you can also call the company or customer hotlines and clarify any further questions.

Notes on Work Safety

- Resin and hardener both contain toxic substances before mixing, so you should always avoid direct skin contact.

- After mixing the two components, a chemical reaction takes place, which produces toxic fumes. To prevent inhalation, you should use a breathing mask with an A2 filter as a protective measure. This protects you from harmful vapors and gases.

- To protect your hands, you should use nitrile gloves. Latex gloves do not provide sufficient protection when working with epoxy resin.

- You should definitely protect your eyes from possible splashes with safety glasses.

- If you are sanding, sawing or drilling the cured resin, you should also wear a respirator or breathing mask. Although the casting resin itself is harmless after curing, toxic dust and vapors may be produced during machining and should not be inhaled.

Tip: When working with epoxy resin, the room in which you work should always be well ventilated. For your own safety, wear the appropriate protective clothing also during further processing.

Early Treatment of Skin Disorders

If you notice any changes in your skin after working with epoxy resin, you should not hesitate to see your doctor as soon as possible. If possible, you should rather consult a qualified dermatologist instead. If the skin reactions are not treated promptly, they often become chronic. Symptoms on the skin can also occur when breathing in the epoxy resin vapors, and skin contact is not absolutely necessary for this.

If you observe the processing and safety instructions, epoxy resin can still be a safe, particularly versatile material.

Sources:

EU Regulation

Toxicology brochure from PlasticsEurope

Larissa Meyer is a 32-year-old mother from Michigan and creative spirit since childhood. Her passion for painting and drawing has led her to an education as an illustrator and a career as a freelance graphic designer. She has a Bachelor of Fine Arts in Illustration and a degree in Graphic Design. Larissa is a talented artist who is able to master a wide range of styles and techniques to bring her artistic vision to life. Her greatest passion is currently fluid painting and epoxy resin art. Larissa’s love for art and her knowledge and experience in illustration make her the perfect Creative Director for our fluid-painting.com team. She is the creative head of our team and shares her passion and knowledge with our community through articles and tutorials.

As a mother of a 2-year-old daughter, Larissa also understands the importance of fostering creativity in early childhood. She uses her experience and knowledge to help other parents inspire their children and develop their artistic skills as well.

Learn more about Larissa Meyer and about us.

![Resin Color and Dye – How to Color Resin [Guide]](https://fluid-painting.com/wp-content/uploads/2020/04/resin-color.jpg)