Best Epoxy Resin for Crafts – Find the Right Resin for your Projects

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

While there is a wide range of different epoxy resins for different applications, finding the right resin for the respective project is not so easy. In this guide, you will get an overview of the best epoxy resins and their application areas.

Table of Contents

- 1 What You Should Pay Attention When Buying Resin

- 2 Differences Between Various Types of Epoxy

- 3 The Best Resins for Epoxy Resin Tables

- 4 The Best Epoxy Resin for Resin Art

- 5 Buy Resin for Floor Coating

- 6 Buy Resin for Epoxy Resin Jewelry

- 7 Buy the Best UV Resin

- 8 Buy the Best Casting Resin

- 9 You Should Know this about Epoxy

- 10 Viscosity – The Fluidity of the Material

- 11 The Processing Time of Epoxy Resin

- 12 Curing Times

- 13 Hardness of the Surface

- 14 UV-Resistance

- 15 Susceptibility to Bubble Formation

- 16 Heat Compatibility of Resin

- 17 Coloring Epoxy Resin

- 18 Weigh and Mix Epoxy Resin

- 19 Painting Background

- 20 Saving Sticky Resin Surfaces

- 21 Frequently Asked Questions and Answers about Buying Epoxy Resin

What You Should Pay Attention When Buying Resin

The Epoxy Resin business has become very popular, which is why there are more and more cheap products that may look very tempting at first. However, we recommend that you choose brand products from well-known manufacturers. Although these are somewhat more expensive, they have much better quality and properties than cheap resins. For your first experiments and test objects, you can of course buy cheaper epoxy resin.

Differences Between Various Types of Epoxy

With resin, we differentiate between casting resin, and epoxy or laminating resin. The two products are basically the same material, but with different properties and therefore different applications.

Casting Resin

- Different mixing ratios

- Thinner consistency (low viscosity)

- Slower curing times

- Longer processing time

- Thicker maximum pouring depth

Laminating Resin

- Simple mixing ratios

- Thicker or more viscous consistency (high viscosity)

- Faster curing times

- Short processing time

- Only thin casting layers possible

The Best Resins for Epoxy Resin Tables

The production of tables made from synthetic resin is becoming increasingly popular. With wood and epoxy resin, beautiful tables can be made in a variety of forms. However, some preparation, and practice, is necessary for the production of one of these stunning pieces. To cast a tabletop with a thickness of 5 cm, a quantity of ten or more kilograms of resin is needed, depending on the size of the table. The thickness of this layer is also particularly important here, because the casting resin must be specially designed for such an application so that such a thick layer is possible in one casting.

If a commercially available, inexpensive resin is used, the exothermic reaction can generate a great deal of heat and thus damage the wood and the surroundings. It is therefore worthwhile to use a special product for this purpose, or with a lot of patience, pour several thin layers on top of each other, and let them harden for several hours.

For tables made of epoxy resin the following properties are particularly important:

- A layer height of up to 5 cm should be possible

- It must be possible to process larger quantities of the resin without it overheating

- To allow the air bubbles to escape better, a longer pot life is recommended

- To avoid yellowing, UV protection should be included

Our Recommendation: INCREDIBLE SOLUTIONS Deep Pour Resin

Deep Pour Resin is a brand from the company Incredible Solutions, which offers high-quality epoxy resins in all areas of application. The products are developed in-house and manufactured in their own production facilities. Deep Pour Resin has been specially developed for processing large quantities and casting deep layer thicknesses of up to 2 inches. It is therefore ideal for casting Resin Tables where larger quantities of resin are required due to the size of the project.

Due to the built-in UV filter, the resin hardly turns yellow and the beautiful transparency is preserved. The resin is relatively thin-bodied and therefore penetrates even into small cracks, which is perfect for this application. The formula ensures that any air bubbles it contains escape almost by themselves. The price is very good for the quality and it is worthwhile to invest a little bit more to get the perfect result.

- Thick pours, low viscosity, and long working time

- Clear results and compatible with pigments and dyes

- 2:1 mixing ratio by volume

The Best Epoxy Resin for Resin Art

Under the term Resin Art, you can find all the techniques that can be used to create decorative and art objects from epoxy resin. There are no limits to creativity: paintings cast with resin and Color Pigments on a wooden painting ground, the production of resin jewelry, up to the casting of geodes and coasters, are all possible. As these applications require mainly thin layers where pigments or liquid paint is mixed in, the resin should not be too liquid. Otherwise, the individual colors will mix with each other and an unwanted shade will be created.

For application in art, there are some specialized products that are specially adapted to the needs of epoxy artists. The focus here is on ensuring that as far as possible no solvents are used, that no volatile organic compounds escape and that very little odor is produced during processing. Professional epoxy resins also use the highest possible quality UV filter to prevent yellowing or fading of the resin and the color it contains. Epoxy always loses a little of its crystal clear transparency and can yellow minimally. However, this is hardly noticeable, especially if colors have been mixed in.

The following must be taken into account when using epoxy resin in art:

- For good color separation, the resin should be medium to high viscosity (rather thick)

- This resin, which was specially developed for coatings, is often called “laminating” resin

- The processing time should be long enough to cast the artwork (approx. 30 minutes)

- UV protection should be included to prevent yellowing and to keep the artwork radiant for as long as possible

Our Recommendation: PRO MARINE Proart Epoxy

Pro Marine Porart EPoxy was developed in such a way that it contains as few toxic substances as possible and is easy to handle. It therefore hardly steams at all and is free of solvents. Nevertheless, the recommended safety measures should always be observed. The high-quality, built-in UV filter protects the cured material from yellowing in the best possible way. Another positive aspect is that the color pigments or color liquids mixed in do not mix together and thus no unintentional dirty color mixtures occur.

- Specifically designed for art projects, excellent color stability

- Very easy to use with 1 : 1 mixing ratio, 100% solids, hard-shell finish

- High gloss and crystal clear, your all-seal solution, excellent air release

Buy Resin for Floor Coating

It is now very common to make floors from epoxy resin. The positive characteristics make it perfect for use in the living space as well as the garage floor. In the living room, resin can be used for all types of floors: from the cellar, to the actual living spaces such as bedrooms and living rooms, to the kitchen or bathroom floor. It is also becoming increasingly popular as a protective layer for existing wooden floors.

It is important that the epoxy floor resin is very hard after curing, but still elastic enough to withstand all loads. Ease of application with these special products for floor coating is also very important. Trapped air bubbles should easily be able to escape. Most of the products can be bought ready-mixed, so you follow fewer steps and the color accuracy is maintained e.g. according to the RAL standard. You can find more information on this topic, and instructions, in our guide “Epoxy resin flooring self-made”.

The following should be considered when choosing epoxy resin products for floor coating

- For a level floor covering the resin should be self-leveling

- Air bubbles should escape by themselves if possible

- The processing time must be long enough to allow larger areas to be processed

- In order to avoid yellowing and color changes due to solar radiation, UV protection should be included

- Good impact and abrasion resistance

Our Recommendation: Rust-Oleum EpoxyShield

Rust-Oleum EpoxyShield is a high-quality sealant for floors. It penetrates into the substrate and binds with it, thus achieving very high stability. You can simply apply it with a lint-free paint roller and it levels itself very nicely. A primer is recommended for the floor.

- Very durable, Formula for garage floors, basements and more

- Hardenes within one day, drive-on ready in 72 hours

- Super adhesion on surfaces, covers up to 500 sq ft

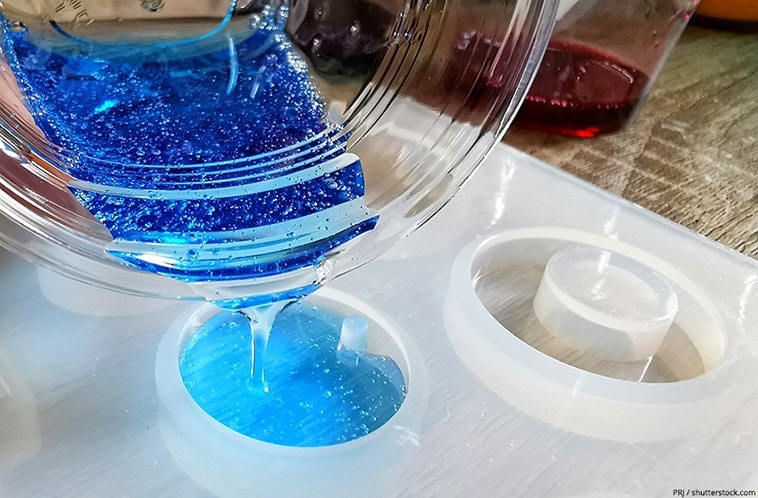

Buy Resin for Epoxy Resin Jewelry

With resin and silicone molds you can cast beautiful jewelry. There are no limits to your creativity, no matter if it is clear or colored jewelry, or combinations of pieces with wood or other materials. It is also possible to cast in objects. In contrast to the casting of larger objects, the maximum layer thickness is not so decisive here. It is much more important to have good UV protection, good processability, and good color separation when using several colors. Crystal clear curing is also important for casting objects. If you pay attention to these properties, there is nothing more stopping you from making your own jewelry from epoxy resin.

These must be taken into account when casting epoxy resin jewelry:

- The resin used should cure as hard as possible so that the jewelry does not scratch easily

- If possible, air bubbles should escape by themselves during pouring or can be removed with a Bunsen burner

- In order to avoid yellowing and color changes due to solar radiation, UV protection should be included

Our Recommendation: PRO MARINE Proart Resin

Pro Marine Proart is a very good all-round resin for a wide range of art applications, and is also well suited for the production of epoxy jewelry. It is characterized by a very good price-to-performance ratio and good color separation. It also hardens crystal clear.

- Specifically designed for art projects, excellent color stability

- Very easy to use with 1 : 1 mixing ratio, 100% solids, hard-shell finish

- High gloss and crystal clear, your all-seal solution, excellent air release

Buy the Best UV Resin

UV Resin is a special type of epoxy resin, which is already mixed and can be used straight from the packaging. The processing time of UV Resin is very good, as it only begins to cure under UV radiation. However, this happens very quickly and the resin is fully cured within a few seconds to minutes. This makes it particularly suitable for small casting molds or surfaces where rapid curing is required, such as repairs, jewelry making, and other indoor applications.

This should be considered when buying UV-Reins:

- Depending on the application it should be a rather thick or thin fluid

- If possible, air bubbles should escape by themselves during pouring or can be removed with a Bunsen burner

- Good curing under UV light is essential, and here a special UV lamp helps for best results

- More odors can escape than with conventional epoxy resin

Our Recommendation: DecorRom UV Resin

The DecorRom UV resin is of high quality and cures beautifully transparent. With UV light the curing is completed after only one to two minutes and air bubbles can be removed quite easily. It is also relatively inexpensive.

- crystal clear curing, high gloss surface

- Really hard surface and very good resistance to yellowing

- Cures in 1-2 Minutes with a powerful UV lamp

Buy the Best Casting Resin

The requirements for resin casting are very different from those for resin paintings or surface coating. When casting molds, deeper layers are often cast, so the resin must not harden too quickly, otherwise too much heat would be generated. Even air bubbles cannot escape if the casting resin becomes solid too quickly. With a conventional laminating resin, only two to three centimeters can be cast, for everything beyond that you should use a special casting resin.

This must be taken into account when buying synthetic resin for casting:

- Casting resins are usually rather thin-bodied (low viscosity)

- The heat development during curing is reduced by a long open time

- A layer thickness of up to 5 cm should be possible

- As the resin is often left transparent when molds are cast (e.g. when objects are cast into the resin), a UV filter should be provided

Our Recommendation: INCREDIBLE SOLUTIONS Casting Resin

The Incredible Solutions Casting Resin is optimally suited for casting molds up to 2 inches. The crystal-clear resin has a working time of up to 24 hours, which is why it is very good at releasing air bubbles almost by itself.

- Thick pours, low viscosity, and long working time

- Clear results and compatible with pigments and dyes

- 2:1 mixing ratio by volume

You Should Know this about Epoxy

Epoxy resin has unsurpassed durability, chemical resistance, and strength during bonding. It has low porosity and is best suited as a protective surface layer. Most epoxy resins are mixed in a two-component process that must be followed exactly as per kit instruction. Each product can vary in its mixing ratio, so you should always read the instructions on the packaging before working with a new brand or product.

You should always remember that after mixing the two components, you only have a maximum pot life of one hour. Therefore, you should be well-prepared and have all the tools and aids at hand beforehand so that you do not lose any time. At the end of the pot life, the unprocessed mixture can become very hot and hardens relatively quickly. Depending on the product, the open time can only last a few minutes, whereas the actual curing process takes several days.

Viscosity – The Fluidity of the Material

Compared to epoxy resins, casting resins are generally thinner mixtures, i.e. low viscosity. These normally harden more slowly and therefore produce less heat, which is why thicker casting layers are possible. However, this poses a problem when using such casting resins: Due to the thin liquid of the mixture, it can run off the edges of the surface. It is therefore necessary to build a barrier or frame to keep the material in the desired position.

To prevent this problem, most epoxy resins are highly viscous, i.e. thicker. However, this only allows thin layers of no more than one centimeter per application. If a thicker layer than recommended is poured, an accelerated reaction may occur, causing the resin to boil and become cloudy and unstable. Therefore high viscosity laminating resins are rather unsuitable for resin casting. With low-viscosity casting resins, on the other hand, layers several centimeters thick can be cast per application. Casting resins with this property are thus well suited for River Tables, molds, figures, and jewelry.

The Processing Time of Epoxy Resin

The working time, open time, or also called pot life, should not be confused with the curing time. As the name suggests, the curing time indicates the time period before the material starts to cure. After this time, the processing of the mixed material is no longer possible and air bubbles can hardly escape.

Casting resins harden much slower and therefore have a much longer working time. The working time of coating epoxies is often 20 +/- 5 minutes. 20 minutes is often not enough to prepare a project properly. When casting in hot environments or by leaving large quantities of resin in the mixing vessel for too long, this time can be shortened considerably.

Curing Times

With cast resins, curing takes place much more slowly than with epoxy resins. Cast resins have a curing time of 36 to 48 hours and epoxy resins cure in 12 to 24 hours. However, epoxy resins start to thicken after only 20 minutes, whereas casting resins can take up to 24 hours. Casting resins can generally be used to produce thicker casting layers, as the heat is dissipated much more slowly than when epoxy resins are cast.

With some coating epoxies, after being in the mixing container for 5 to 10 minutes, it can cause them to react faster and generate excessive heat.

Hint: When casting an epoxy coating that is too thick (like in a flow table), the epoxy may heat up and break, ruining the project.

Hardness of the Surface

As a rule (with a few exceptions) epoxy resins are harder than casting resins. With cast resins, it is often possible to vary the mixing ratios, which also allows the hardness to be varied. A good example is the casting resin used as artificial water for a vase.

If a casting resin without flexibility is used, the vase will break as soon as the glass expands and contracts. More flexible mixtures are therefore required for this type of application, which can usually be achieved by varying the amount of hardener used. However, since every resin is different, you should first check whether the resin you choose is suitable for your project.

Hint: Laminating resins usually have a better scratch resistance than casting resins. It is therefore ideal if resin tables or kitchen worktops are coated with a laminating or epoxy resin or a protective lacquer at the end.

UV-Resistance

Both casting resins and epoxy coating resins may contain UV stabilizers. For thick, uniform casting projects, yellowing due to UV exposure may be more obvious, as these projects are not supported by the color of wood grain, paint, stain, etc.

Some epoxy resins are more resistant to yellowing than others. In the case of coating epoxies, yellowing is often better masked or distorted when supported by the grain of wood, or darker colors and glazes on the substrate of the project. It is important to note that most casting resins and coating systems are not recommended for permanent outdoor use or direct UV exposure.

Susceptibility to Bubble Formation

Both resins are equally susceptible to bubble formation on the substrate and the enclosed parts. With casting resin, bubbles may be less noticeable, as it is a very thin material where bubbles can rise to the surface and eventually burst more easily.

With good project preparation, however, bubbles can be significantly reduced within both materials. Porous surfaces, such as wood, should first be given a thin sealant. Through a thin sealing layer, the epoxy resin can flow into all porous areas and seal them, and the air should rise slightly to the surface. Items that are to be cast should also be sealed before you add them to your project. Items with a lot of grooves, corners, and open areas will often release air into your epoxy project.

Heat Compatibility of Resin

Most casting and epoxy resins intended for the average do-it-yourselfer are not high-temperature epoxies. High heat epoxy systems can be quite expensive. As a rule, both casting and epoxy resins begin to soften at about 120 °C to 150 °C. This is especially important for those who work with kitchen covers, tables, coasters, and other projects that may come into contact with hot objects such as pots, pans, and coffee cups. Conversely, epoxy can withstand temperatures well below 0 °C after curing.

Heat resistant epoxy resin is available in several variations. A resin available for do-it-yourselfers usually only withstands temperatures of up to 150 degrees, whereas other industrially used epoxy resins can withstand the extreme heat of up to 600 degrees. These resins, specially formulated with fillers (e.g. quartz), offer high heat curing and abrasion resistance.

Coloring Epoxy Resin

For coloring epoxy resin there is a wide range of liquid colors, color pastes, and color pigments. However, you should make sure that it does not contain any water, as this can lead to unwanted side effects. With the right epoxy resin paint, coloring works without problems.

Weigh and Mix Epoxy Resin

Keeping to the exact mixing ratio is essential for the successful fulfillment of your projects. Most resin systems are weighed with a scale. Once the two components are poured into each other, you should start the mixing process and carefully stir the mixture for at least two minutes.

Painting Background

You can basically cast epoxy resin on almost any grease-free and cleaned surfaces. For the production of epoxy resin paintings, we recommend the use of wooden painting backgrounds. In contrast to canvas, these do not sag and are therefore ideally suited.

Saving Sticky Resin Surfaces

If you have already worked on a project and nevertheless have a sticky resin even after a few days, you can still save it. Probable reasons are that you have not kept to the mixing ratio, the product used has expired or the environmental conditions were not the best. You can also find more about “Mixing epoxy resin” on this page.

The following measures will help you in such a case:

- First, you should scrape off the sticky resin and dispose of it. Remove as much material as possible.

- After you have removed all the liquid resin, you can correct the defects by filling in the gaps, craters, or holes. Apply the new resin only to the affected areas.

- After curing, lightly sand the entire object, including the patched areas.

- Then you wipe off all the dust and get ready to apply your second coat.

- Even if it does not look like this at first, as soon as the second layer is applied, all errors should be corrected. If you have followed these steps correctly, your object will again be perfect and without any sticky spots.

Frequently Asked Questions and Answers about Buying Epoxy Resin

We are regularly asked questions about buying synthetic resin, which we are happy to answer here.

Where to Buy Epoxy Resin?

Ideally, you should buy epoxy resin on the Internet. In addition to the significantly lower price, you have the widest selection of products, and everyone can find the ideal product for their project. Because there is not only one epoxy resin, but many different products with different properties, you may not always find exactly what you need locally.

How Much Epoxy Resin do I Need for my Project?

We have created a comprehensive Epoxy Resin Calculator that can help you calculate the amount you need.

Which Dyes can be used to Color Epoxy Resin?

For coloring epoxy resin there is a wide range of coloring agents available. You can use special epoxy resin color pastes, color pigments, airbrush paints, and alcohol inks.

How to Mix the Epoxy Resin Components?

When mixing epoxy resin, you must be very careful to ensure that the two components mix well and that the material hardens optimally. You can find more on this topic in our separate article “Mixing epoxy resin”.

Larissa Meyer is a 32-year-old mother from Michigan and creative spirit since childhood. Her passion for painting and drawing has led her to an education as an illustrator and a career as a freelance graphic designer. She has a Bachelor of Fine Arts in Illustration and a degree in Graphic Design. Larissa is a talented artist who is able to master a wide range of styles and techniques to bring her artistic vision to life. Her greatest passion is currently fluid painting and epoxy resin art. Larissa’s love for art and her knowledge and experience in illustration make her the perfect Creative Director for our fluid-painting.com team. She is the creative head of our team and shares her passion and knowledge with our community through articles and tutorials.

As a mother of a 2-year-old daughter, Larissa also understands the importance of fostering creativity in early childhood. She uses her experience and knowledge to help other parents inspire their children and develop their artistic skills as well.

Learn more about Larissa Meyer and about us.