Rust-Oleum Epoxy Flooring – A Rust-Oleum Epoxyshield Review

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

Do you have a concrete garage floor that has seen better days? Why not try applying an epoxy coating for a renewed look? Epoxy coatings also provide many other benefits as well. Epoxy is considered a durable finish and has become one of the best and more popular choices for garage flooring. There are many professional and DIY products on the market and one of the more popular and trusted brands that provide these products is Rust-Oleum. Amongst their many choices is the EpoxyShield garage floor coating.

Table of Contents

What is Epoxy Flooring?

You might have heard something along the lines of painting epoxy onto your floor, but this must not be confused with the epoxy floor coating being a type of paint. Epoxy is not paint; the paint is an acrylic latex product. However, you might get a paint that has a small amount of epoxy added to it so as to increase durability, but it still remains a paint. For example, the Rust-Oleum concrete paint is a one-part acrylic-base paint.

Epoxy, on the other hand, is a two-part thermosetting resin. Once the two parts, being the resin and hardener, are combined, a reaction occurs. This reaction causes the epoxy to harden or cure, unlike paint which dries. The reaction produces a durable coat that is much thicker than paint.

The result is an epoxy floor that can withstand spills, heavy traffic, and will last for an exceptionally long time. The Rust-Oleum floor epoxy will offer you just that.

When it comes to DIY products and other commercial or industrial products, there are differences in composition and price. The epoxy made for commercial use is best, as it is solid-based. This means that they contain 100 percent solids, and that what is applied onto the floor will remain on the floor. In other epoxies with less of a percentage, a part of the product evaporates, which could be water or solvents. For example, if you see an epoxy that says it is 50 percent solid, this means that half of the coat you apply is going to evaporate.

The higher the grade of epoxy, the more expensive it is. Thus, epoxies with fewer solids are cheaper and will reduce the effectiveness of the final finish. This does exclude topcoats and primers, however. The quality also affects the thickness of the epoxy, where the thicker the epoxy, the better. It is the thickness that helps avoid lifting when, for example, hot tires come into contact with the surface. Various additives can also be added to enhance the benefits of the epoxy further.

Now that we have a basic idea of what epoxy is, we can have a look at some of the benefits.

Benefits of an Epoxy Floor

The benefits of Rust-Oleum floor epoxy and other epoxies are many. However, if you are still wondering if it is something you should be doing, have a look at some of the benefits below to see if it will help to make your mind up. Once an epoxy floor has been properly applied, it should provide many years of protection and good looks.

Provides Durability

When it comes to a tough finish, epoxy is an excellent choice for your garage floor. The epoxy coat will help to withstand chemicals, impacts, stains, heat, water, and abrasions. Those little oil spills that seem to remain on the surface will be something of the past. You also do not have to worry about heavy items falling onto the floor or general wear and tear.

Helps to Cover Problem Areas

Tired of looking at that mess on your garage floor that you cannot seem to get rid of? Epoxy will add a smooth and shiny surface, covering up any blemishes that were on the original surface. To do this even more effectively, you can choose an epoxy paint and color that you prefer. In many cases, an epoxy kit like the Rust-Oleum garage epoxy comes with small chips that you can add to create a nice sparkle and provide some traction. In the end, you will have a much better-looking surface than plain old cement.

Worried About the Smooth Surface?

You can simply include a slip-resistant additive, which will prevent any nasty falls, especially if the epoxy gets wet. This is a great idea for those that live in areas where it rains or snows a lot. This brings us to our next benefit.

Easy to maintain and clean

Since it is resistant to spills, as it has a non-porous surface you can easily just spray down the surface with a hosepipe. You can also vacuum, sweep, or wipe it clean with some warm water. Preferably, do not use any acidic cleaning products, as this may dull the surface over time.

Rust-Oleum Epoxy Flooring

The Rust-Oleum company has been around for quite a few years. It all began with Captain Robert Fergusson, who discovered ways to keep his boat looking ship-shape. As with many discoveries, it happened that one day by accident, some fish oil was spilled, and this helped to stop the corrosion of the metal deck. This then steered the way to the development of the Rust-Oleum Company in 1921.

Today, they offer an array of products that are innovative and effective, using resins that come from polyurethanes, alkyds, and, of course, epoxies. One of its products, Rust-Oleum Garage Epoxy, offers high-performance coatings. The EpoxyShield garage floor coating offers great protection, and you can even do it yourself. However, there may be some work, time, and preparation needed to create the best results.

Rust-Oleum epoxy flooring includes a range of products from the EpoxyShield garage floor coating and other professional coatings to a concrete sealer and resurfacer.

Best Garage Floor Coating: RUST-OLEUM Garage Floor Kit

The EpoxyShield garage floor coating is a two-part system that can be applied to indoor concrete floors, making it a perfect fit for your garage floor. The final finish is durable and will protect the floor from spills. The product instructions say that it can cover about 250 square feet and that you should not have any problems with hot tire pick-up. You should be able to walk on the finished surface within 24 hours, and a vehicle can stand on it in 72 hours. The product is water-based and comes with a two-part epoxy system, concrete etcher and concentrated cleaner, decorative chips, a stirring stick, and instructions.

Pros

- Exceptionally durable

- Can walk on the finished surface after 24 hours

- A semi-gloss or solid color can be added

- Water- and chemical-resistant

Cons

- Can only be used on indoor surfaces

- Has an odor, so wear a respirator, gloves, and goggles

Some people reported that their product began to separate after a while and that it shows tire marks. So, if you wish to avoid this, it is best to get in a professional to do your floors. It may be more expensive, but will most probably save money you over time.

Best Epoxy Paint: RUST-OLEUM Concrete Paint

Amongst the EpoxyShield range is the Rust-Oleum Concrete Paint. It has an advanced acrylic formula, providing a weather-resistant coat that is easy to clean. The one-part acrylic coat is self-priming and can be used on your patio or garage surfaces. Walls and fixtures can also benefit from this product. The final finish is smooth and should not chip under difficult conditions.

Pros

- Easy to apply and keep clean

- Weather- and UV-Resistant

- Can be used on indoor and outdoor surfaces

Cons

- May begin to peel and chip

Although two-part epoxies offer more durability, the one-part epoxy, on-part acrylic formula belonging to Rust-Oleum concrete paint is great to use on aged and cracked concrete surfaces. It will smoothen and brighten the surface whilst adding an extra layer of protection.

Applying Rust-Oleum Garage Epoxy

One of the most important steps when applying any floor coating is floor preparation.

- First, you will have to find an alternative space for your car and anything that is on the floor.

- There will be dust and dirt, so remove this with a vacuum cleaner or broom.

- There should be directions together with the epoxy floor coating products, so make sure that you follow these exactly.

Once the surface dust has been eliminated, you need to apply a degreaser.

- A garage floor will inevitably have oil or grease marks, and the degreaser will help to remove them.

- Next, apply the Rust-Oleum concrete etch product that comes with the EpoxyShield garage floor coating kit. This prepares the concrete surface for painting.

Images: bhakpong – stock.adobe.com

Images: bhakpong – stock.adobe.com

Note that a slightly different procedure will be involved for preparing concrete surfaces that have previously been coated or sealed.

- Ensure that the concrete surface has been thoroughly prepared and is completely dry. There should be no moisture on the floor, as this will prevent the epoxy from adhering properly to the floor once applied.

- If there are any flaws or holes, you can use a compatible epoxy cement filler.

Once you are positive that all the preparation work is complete, you can begin applying the Rust-Oleum garage epoxy. You will need:

- A mixing bucket,

- A paintbrush and roller, and

- Soapy water and a rag.

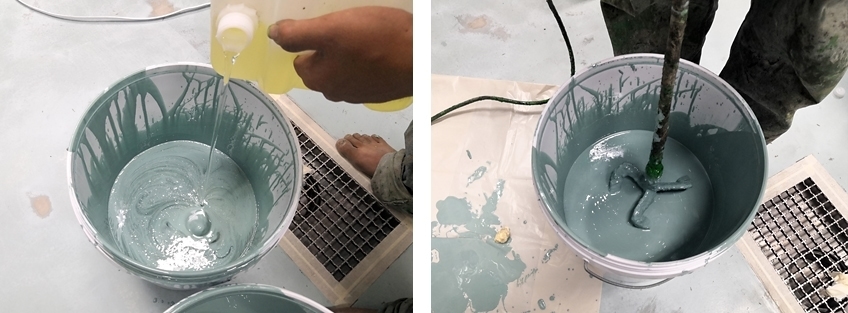

You will now have to combine the two-part epoxy mixture.

- Once you have stirred the resin base, you can add the catalyst or hardener. Stir until everything has been mixed evenly.

- This mixture must now be used within a certain time, usually within 1 to 2 hours.

Images: Chinnabanchon9Job / shutterstock.com

Images: Chinnabanchon9Job / shutterstock.com

You can take the paintbrush to apply to the edges and other difficult places, and then use the roller to apply the product to the rest of the flat surface area.

- Using a roller with a longer handle will be more effective during application.

When you have covered a small area with the epoxy, take the decorative chips and spread them over the area.

- Paint and sprinkle the chips until the entire surface has been done.

- It is best to do the work in 60- to 85-degree Fahrenheit temperatures during application for the best results.

Images: Salamatik / andrey gonchar – stock.adobe.com

Images: Salamatik / andrey gonchar – stock.adobe.com

Once done, clean the paintbrushes straightaway with some warm water and soap.

- Let the coating dry completely for 48 to 72 hours.

- Wait for at least a week before allowing a car to stand on the surface.

Maintaining EpoxyShield Garage Floor Coating

Applying an epoxy floor coat is an excellent choice in both residential and industrial cases. Maintaining the epoxy floor is easy, but it does require regular cleaning, especially in an industrial setting.

Images: Bannafarsai_Stock, BELL KA PANG / shutterstock.com

Images: Bannafarsai_Stock, BELL KA PANG / shutterstock.com

- Keep the surface dirt-free by removing sand and grit regularly.

- Try not to use soap-based cleaning products, as it can leave the surface looking cloudy.

- Warm water and a mop should be all you need. Avoid using acid-based cleaning products.

- Clean spills straight away.

Frequently asked Questions

Is Epoxy a Good Product to Use on Concrete Floors?

An epoxy coating for concrete is the best choice for protecting your floor whilst giving it an attractive appearance.

How Difficult is It to Apply Rust-Oleum Floor Epoxy?

The epoxy provides a durable and shiny finish if done correctly. So, you will need to follow precise instructions, prepare the concrete surface thoroughly, and allot the time to do it all. However, the results are long-lasting and rewarding.

Does an Epoxy Floor Coating Last Long?

Yes, epoxy is durable and easy to keep clean, and should give you five to ten years of durable finish.

At What Temperature Should I Apply the Epoxy?

The best temperatures to work in is 60 up to 85 degrees Fahrenheit. Also, take note of night-time temperatures, as it should not go below 65 degrees Fahrenheit a day or two before you apply the epoxy. If done at an incorrect temperature, it will affect how the epoxy adheres to the concrete surface.

Should I Add a Topcoat?

Some would say that you do not have to add a topcoat, but others will tell you it is needed. The topcoat will add another layer of protection and could prevent things like hot tire pick-up.

Larissa Meyer is a 32-year-old mother from Michigan and creative spirit since childhood. Her passion for painting and drawing has led her to an education as an illustrator and a career as a freelance graphic designer. She has a Bachelor of Fine Arts in Illustration and a degree in Graphic Design. Larissa is a talented artist who is able to master a wide range of styles and techniques to bring her artistic vision to life. Her greatest passion is currently fluid painting and epoxy resin art. Larissa’s love for art and her knowledge and experience in illustration make her the perfect Creative Director for our fluid-painting.com team. She is the creative head of our team and shares her passion and knowledge with our community through articles and tutorials.

As a mother of a 2-year-old daughter, Larissa also understands the importance of fostering creativity in early childhood. She uses her experience and knowledge to help other parents inspire their children and develop their artistic skills as well.

Learn more about Larissa Meyer and about us.