Heat-Resistant Epoxy – Do You Get High-Temperature Epoxy?

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

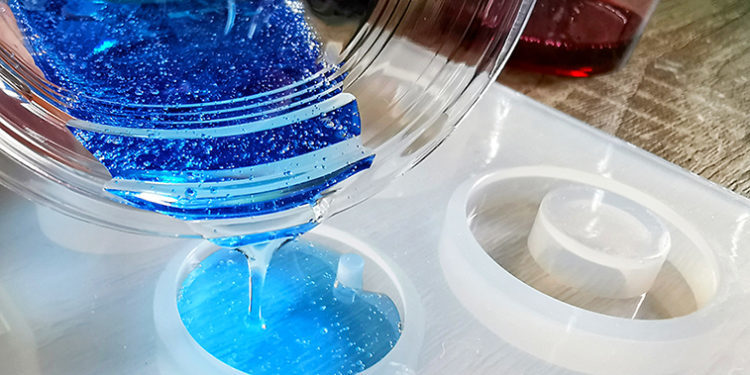

Using epoxy resin for countertops has become immensely popular in recent years, particularly since it allows you to do it yourself, and you can create exactly the look you want. However, we have all heard that cured epoxy resin has a maximum temperature limit. So, what should you do if you need your resin to withstand higher temperatures? This post about heat-resistant epoxy resin will address some of the more common concerns.

Table of Contents

What is High-Temperature Epoxy?

Most DIY epoxies can handle the heat from a cup of coffee, but not that of a hot dish straight from the oven. Thankfully, there are high-temperature epoxies that can attain a higher temperature tolerance. High-temperature epoxies can withstand temperatures of up to 600°F (315°C). These typically have special additives that make them more tolerant of high temperatures, such as that of quartz.

An added advantage of this is having a much higher resistance to abrasion as well. Heat-resistant resins are formulated with a rigid rod structure as opposed to the more common flexible matrix structure, thus allowing it to handle excessive heat.

In addition to heat, another factor to take into consideration is humidity. Even at room temperatures, if the relative humidity is constantly in the region of 95%, epoxy resins could swell and become less solid. If the temperature goes any higher, this phenomenon just becomes more apparent.

Epoxy Temperature Limits

Typically, epoxies can withstand colder temperatures relatively well, and can even handle temperatures that reach below freezing. However, most epoxy resins will start to soften at around 140-150°F, but will harden again if the temperature is then lowered.

At even higher temperatures, the epoxy may be prone to melting and could stay in that state despite cooling it down afterward. In this case, you would have to fix or completely redo your epoxy countertop.

An alternative is to use high-temperature epoxy resin. This type of resin has been specially formulated to withstand higher temperatures, with most commercially available products able to withstand temperatures of up to 600°F (315°C).

Incredibly, some industrial epoxy products used in aircraft manufacturing can even cope with temperatures over 2700°F (up to 1500°C)!

The Best High Temp Epoxy: STONE COAT COUNTERTOPS Casting Epoxy

Stone Coat is a proudly American line of epoxy resin products, which feature a range of desirable characteristics. It is durable, scratch-resistant, easy to work with, and has a stated heat resistance of up to 475°F (246°C)! That is quite impressive for a consumer-grade epoxy. It has an extended working time and is engineered for maximum UV resistance.

- Resistant to heat, water, and UV rays

- Durable and crystal-clear finish

- Easy to use

The product has a simple mixing ratio of 2:1 by volume and will cure to the touch within just 24 hours. Although the epoxy will cure within 72 hours, it will not become fully heat- or UV-resistant until a period of 30 days has passed.

Pros

- Heat-resistant up to 475°F

- Maximum UV resistance

- Extended working time of up to 45 minutes

- Zero VOCs

- Crystal-clear when cured

- Easy 2:1 mixing ratio

- Scratch-resistant

Cons

- A little on the expensive side

- Long curing time

How to Work with Stone Coat Epoxy

Mix the resin and hardener in a 2:1 ratio by volume. You can use an electric drill and a mixing attachment on a low speed for this. Make sure to mix for around 3 to 5 minutes so as to ensure that the two components are thoroughly mixed.

Make sure that the surface you want to coat is free of any dust or oily substances, as this will negatively affect the bonding of your epoxy. The depth of your layers will depend on whether you are using casting resin or laminating resin.

Use a trowel to spread the epoxy evenly over your countertop. An added advantage to this resin is that it levels itself automatically. An angled brush can then be used to chop the surface so as to remove any trowel lines whilst also mixing the epoxy one final time.

When using a heat gun to pop any bubbles in the epoxy, keep it around 2 to 3 inches above the surface, and use it in smooth, even sweeps. After the working time of around 45 minutes, the epoxy will be dry to the touch in 24 hours. You can begin light use after around 72 hours, and the resin will be fully cured after 7 days. Full UV- and heat-resistance are attained after 30 days.

What Can Reduce Temperature Resistance?

In general, epoxy resins that are fully cured will withstand day-to-day wear and tear relatively well. However, some factors may lower the temperature tolerance of your epoxy resin. These include:

- Adding pigments, color pastes, or alcohol inks. Each of these can lower the overall heat tolerance of the finished epoxy resin project. For pieces that will come into constant contact with heat, it is best to make sure of the individual properties of the pigments you will use. Ask the manufacturer for information on these, or read the instructions that are supplied with the products.

- Not properly mixing the resin and hardener. Recommended mixing times are at least 3 minutes so as to allow the two components to mix thoroughly. Remember to scrape the sides and bottom of the mixing container when mixing

- Not using the correct mixing ratio. Since different brands of epoxy resin may have different mixing ratios, it is critical that you make sure of this before measuring the resin and hardener. While most products will have 1:1 mixing ratios, others have a 2:1, or even 3:1 ratio.

- Not waiting until the epoxy resin has fully cured. If you apply excessive heat to the epoxy before it has fully cured, it may affect the curing process and cause issues with the heat tolerance of the final product.

Tips and Tricks

- For extra protection and durability, apply a final clear coat when you are finished with your project. This will help to protect the colors and artwork you embedded in the epoxy resin.

- Pour the hardener into the mixing bowl or container first, and then add the resin. The thinner, more liquid hardener will mix more thoroughly with the resin, which means that there will be fewer issues with your final resin piece!

- Always make sure of the mixing ratio for the product you are using. For Stone Coat Epoxy, it is a very straightforward 2:1 ratio by volume.

- A torch or heat gun can help you to get rid of unwanted air bubbles in your poured epoxy with ease. Just be careful not to keep the heat on a specific spot for too long, as this may cause problems with the curing process.

- When igniting your torch or heat gun, aim it away from your project at first. This way, any dust that may have settled in the nozzle will not be blown onto your uncured resin, where it will be near-impossible to remove!

- When wiping any surfaces before a pour, add a little bit of isopropyl alcohol to your rag. This will grab any residual dust and grime and give you a clean surface to work on.

As you can see, you can easily have an epoxy countertop in your home that is not only eye-catching, but also tolerant of the heat given off by hot plates, mugs, and the like. Just follow our advice above, and you will have a product to be proud of in no time!

Larissa Meyer is a 32-year-old mother from Michigan and creative spirit since childhood. Her passion for painting and drawing has led her to an education as an illustrator and a career as a freelance graphic designer. She has a Bachelor of Fine Arts in Illustration and a degree in Graphic Design. Larissa is a talented artist who is able to master a wide range of styles and techniques to bring her artistic vision to life. Her greatest passion is currently fluid painting and epoxy resin art. Larissa’s love for art and her knowledge and experience in illustration make her the perfect Creative Director for our fluid-painting.com team. She is the creative head of our team and shares her passion and knowledge with our community through articles and tutorials.

As a mother of a 2-year-old daughter, Larissa also understands the importance of fostering creativity in early childhood. She uses her experience and knowledge to help other parents inspire their children and develop their artistic skills as well.

Learn more about Larissa Meyer and about us.