Types of Resin – Looking at the Different Types of Resin

This post may contain affiliate links. We may earn a small commission from purchases made through them, at no additional cost to you.

Working with different types of resin can be useful for certain projects. These can be used as epoxies, or they can be molded and fitted to form various shapes like clay. Resins can also be used as natural adhesive options, as they have the ability to blend seamlessly with your surface once dry. In this article, we are going to discuss the different types of resins and how they are used.

Table of Contents

Understanding the Different Types of Resin

There are a few different uses and types of resin. Deciding on which one to use is based on the type of resin you pick as well as the job you are intending to use it for. One rule that applies to all different types of resins is to always wear a mask, as these materials give off dust particles that can be very harmful if inhaled. Different types of resin include the following:

Let us explore each of these in detail below.

Types of Epoxy Resin

Types of epoxy resin are a more common and versatile choice of resin for most projects. This option is highly durable and will give you the longest-lasting results. These are quite thick and produce layers of up to five millimeters each. So, quite a bit more than your UV resins. However, they do not hold up well in high-moisture conditions.

Using types of epoxy resin may be a bit more time-consuming as they usually come in a double pack with two products (a resin and hardener). You need to mix up both products before you can apply it in order to elicit the chemical reaction that results in the resin hardening. As they are so thick, they will take longer to dry and will need at least three full days to cure completely.

PROS

- Highly durable

- Thicker layers mean it will last longer

- Can be used for a variety of projects, including jewelry making and as an adhesive

- Affordable and readily available

CONS

- Not suited to environments with a lot of moisture

- Takes a long time to dry completely

- More time consuming

- May turn yellow if exposed to light

Coating Resin

Also known as laminating resin, this type of epoxy resin is used for sealing and coating objects. This resin has a high viscosity, meaning that it is very thick and will therefore leave a durable and high gloss finish on your surface. Coating resins are a wonderful sealant option for concrete and other porous surfaces.

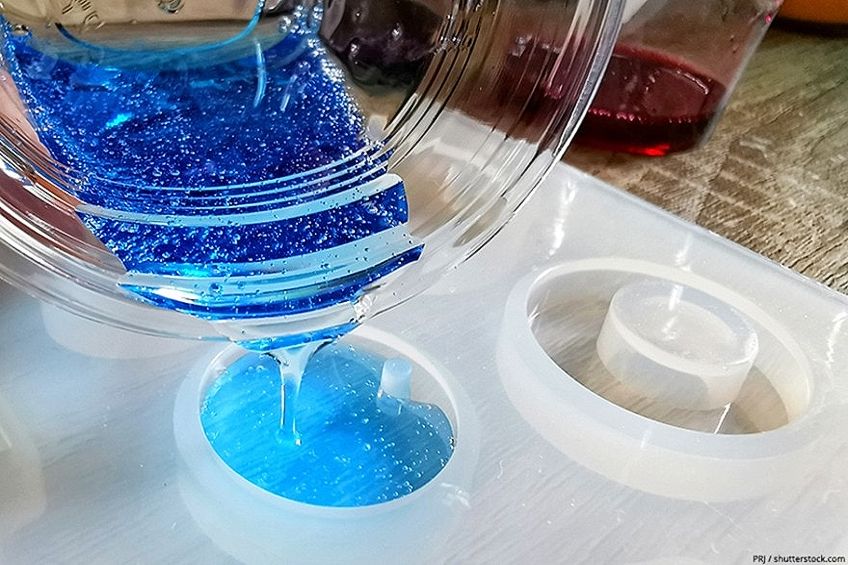

Casting Resin

This type of epoxy resin is often used for making molds and casts of small-scale objects. Due to its thinner consistency, it dries fairly quickly and will do a great job at easily filling holes in certain surfaces. This resin is used more for jewelry making, molds for figurines, and even in dentistry.

Using Other Types of Resin

Depending on what you are using the various types of resin for, the application method may vary. If you are using it to coat a surface, you will need to apply the resin in layers, ensuring that you allow for sufficient drying time between each coat. This resin can also be sanded over between layers to ensure smoother results. Sanding should not need to be done after the second layer. These resins take a long time to cure, but are touch-dry relatively quickly.

UV Resin

This resin option is pretty different from the other types of resin available. UV resins do not dry on their own as other options do. They will remain wet until exposed to a source of ultraviolet light or irradiation. Using a UV lamp is the simplest way to do this. This will effectively cure your resin and is perfect for smaller projects and areas. This choice is also much thinner than other types of epoxy resin, thus creating layers up to a thickness of 1 mm.

When choosing to use a UV option, you should be aware these are not the most durable. These resins will need to be re-applied and touched up twice a year for proper maintenance, and will not protect your surface from damage or heat.

PROS

- One simple formula

- Best used for small areas and projects

- Thinner layers mean this product dries quickly

- Remains wet until it is exposed to the UV lamp, meaning added workability

CONS

- Not as durable as other types of epoxy resin

- Must be maintained and reapplied twice a year

- Will only dry and cure properly with the use of UV irradiation

- Will not withstand heat or scratches

- Can be expensive

- Not suited to larger projects

Using a UV Resin

Applying a UV resin is as easy as painting it over your surface. For added effects, you can also add in colors or tints to it in order to create interesting designs and patterns. You will then use your lamp to start the drying process. The strength of your bulb should be a minimum of four watts to work effectively. This should not take longer than five minutes. If you would then like to add more layers, you can. Be sure to wear a protective mask as even when dry, these fumes are toxic.

Synthetic Polyurethane Resin

This type of resin is part of the synthetic group, which makes it a great choice for making molds. These have more of a plastic consistency, which aids in their flexibility and their ability to be manipulated. This also makes this type of resin stronger at resisting scratches and less likely to turn yellow. These are usually used for flooring, paints, coatings, and adhesives.

This resin option is a great choice when wanting to protect outdoor areas or even cables from moisture and other elements. Polyurethane resins work with the same two-part process as types of epoxy resin. This means that you will need to be careful when combining the products so as to ensure you have the correct ratios. Although this resin option is waterproof when dry, it will not work if applied to a wet surface.

PROS

- Easily manipulated and flexible

- Suited to outdoor projects

- Scratch-resistant

- Will not yellow

- Can be used for various projects

- Dries quickly

- Will protect against the elements

CONS

- Will not stick to wet surfaces

- Moisture will cause your mixture to foam

- Fumes are very strong, even while drying

- Adhesion qualities are not as durable as types of epoxy resin

Using a Polyurethane Resin

Because this solution is so versatile, the method used will be based on what you are doing with your resin. If you are thinking about creating a mold, you would mix your product up according to the product directions and then apply it to your mold.

Polyester Fiberglass Resin

Polyester resins fall under the types of fiberglass resins, and these are used for bigger jobs. Because of its waterproofing properties, it can even be used outdoors. Commonly, polyester resin is used for building ponds, pools, and other watercrafts. This resin can also be used to build models such as boats, planes, and cars.

PROS

- Durable and waterproof

- Great for big projects

- Great for exterior use

- Readily available and affordable

CONS

- You will need to mix and make up the substance yourself

- Very strong smell

Using a Polyester Resin

Just like our other two-part resins, the same will need to be done when using your polyester option. The key here is consistency when adding your elements and making sure you have the correct product ratios for optimum results. This mixture can be used for laminating or making molds. When using these types of fiberglass resin, you will need to use fiberglass sheets and mats in order to get the ideal shapes and molds you are after.

There you have it – all the basics on the different types of resin out there and what you can use them for. Have fun with your projects!

Frequently Asked Questions

What Types of Resin are There?

There are a few kinds of resin one can use based on the purpose of one’s project. Some resins work best for indoor projects, as they will not protect your surface from heat and moisture. Others work well as sealants or for outdoor applications.

Are There Different Types of Epoxy Resin?

Types of epoxy resin do not differ that much, but their differences allow for more versatility. Normal epoxy resin can be used for many things including making jewelry, or it can also be used as an adhesive. casting resin and coating resin are also types of epoxy resin. Casting resin is great for making figurines and small molds, while coating resin works well for high-gloss finishes outdoors.

What are the Different Types of Resin Used For?

There are different types of resin for different uses. If you are looking at sealing and coating your floors, then you may like to try a polyurethane resin for a quick application that is scratch-resistant. If you are looking at building an outdoor pool or sealing a small boat, then choosing types of fiberglass resin would be ideal for the job as they are waterproof when cured. The type of resin you choose will be based on your project requirements.

Larissa Meyer is a 32-year-old mother from Michigan and creative spirit since childhood. Her passion for painting and drawing has led her to an education as an illustrator and a career as a freelance graphic designer. She has a Bachelor of Fine Arts in Illustration and a degree in Graphic Design. Larissa is a talented artist who is able to master a wide range of styles and techniques to bring her artistic vision to life. Her greatest passion is currently fluid painting and epoxy resin art. Larissa’s love for art and her knowledge and experience in illustration make her the perfect Creative Director for our fluid-painting.com team. She is the creative head of our team and shares her passion and knowledge with our community through articles and tutorials.

As a mother of a 2-year-old daughter, Larissa also understands the importance of fostering creativity in early childhood. She uses her experience and knowledge to help other parents inspire their children and develop their artistic skills as well.

Learn more about Larissa Meyer and about us.